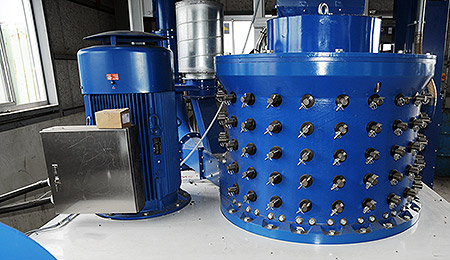

swissRTec Delamination Mill

Waste Electrical and Electronic Equipment :: Auto Shredder ResidueCable :: PCB :: Aluminium Composite and many more

Developed especially to handle pre-shredded, hard and wear intensive composite materials, the Delamination Mill from swissRTec is an excellent solution for the processing of electronic waste, auto shredder residue, printed circuit boards and materials from other waste streams.

The shredded input materials enter the Delamination Mill at the top. Very strong forces act on the materials, positively connected parts are broken apart, and material composites are delaminated at the phase boundaries. During the process the metals take on a globular shape which simplifies the downstream separation and results in a high output quality and yield. A further size reduction also takes place during processing.

The industry leading swissRTec Delamination Mill operates at a relatively low processing speed thereby saving energy and extending the lifetime of the tooling substantially.

The unique advantages of the swissRTec Delamination Mill technology have been proven with satisfied customers worldwide.

Product Advantages

- Developed for wear-intensive composite materials

- Excellent globular forming of metals

- Effective ball shaping of fine copper from hair wires and PCB

- Low rotor speed

- Maintenance friendly, long service intervals

- Fast rotor change

- Integrated machine protection

- Solid, rugged construction combined with safe operation

- Easy integration into existing plants